The welding rotator is a welding auxiliary device, which is mainly used to drive round welded rotation and complete welding of ring welding. The welding rotator can drive the welding parts to rotate the welded parts by the friction between the welding parts and the active roller. The welding speed can be adjusted by the speed of the active roller on the welding rotator. The design of the welding rotator makes the workpiece is not easy to deform and slide when rotating, ensuring the quality and efficiency of welding.

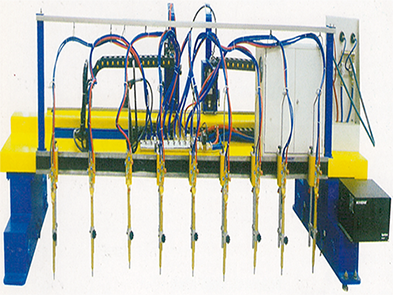

轨距Rail span(mm) | 3000-6000 |

轨长Rail length(mm) | 15000 |

有效行程Effective route(mm) | 12500 |

切割宽度Cuting width(mm) | 80~3200 |

切割速度Cuting speed(mm/min) | 20~6000 |

调速方式Speed control | 无极调速Stepless speed control |

数控割炬CNCatting torch | 9组9groups |

纵向直条割炬 | 2组2 groups |

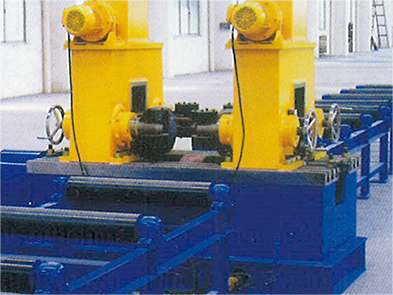

H-beam steel auto assembling machine: The Process includes clamping and alignment of web and flange, and automatic tack-welding is controlled with PLC. The main machine is driven by A.C.inverter, stable and reliable. The upper press-beam is guided through the left and right four rails, ensuring steady clamping for long-term use.

型号Model | 适用腹板规格 | 适用翼板规格 | 适用工件长度 | 装机功率 | 组立速度 | ||

厚度(mm) | 高度(mm) | 原度(mm) | 高度(mm) | ||||

Z15/ZLJ15 | 32 | 200~1500 | 40 | 200-800 | 4000-15000 | 11.7 | 0.5~6 |

Z18/ZLJ18 | 32 | 200~1800 | 40 | 200-800 | 4000~15000 | 11.7 | 0.5~6 |

Z20/ZLJ20 | 32 | 200-2000 | 40 | 200-800 | 4000~15000 | 11.7 | 0.5~6 |

H-beam steel auto welding machine: There are two models, LHA gantry type automatic welding machine and LHT double column-beam automatic welding machine. It adopts A.C. inverter control, with functions of stable running and fast traveling speed; The seam-tracking arc-guide mechanism is a three-spindle system to guarantee the alignment without aberrancy. The main frame and welding machine are integrated control, with a flux auto-recovering system and it is easy to operate with high efficiency. LHT double column-beam automatic welding machine can weld two pieces of beam at the same time, and the web height of the beam is not limited by the main machine.

型号Model | 轨距 | 控制形式 | 适用工件腹板高度 | 适用工件翼板高度 | 适用工件长度 height | 焊接速度 | 功率 |

LHA | 4000mm | 中控 | 200~1200mm | 200~800mm | 4000~15000mm | 0.24~2.4m/min | 9kw |

4000mm | 侧控 | 200~1500mm | 200-800mm | 4000~15000mm | 0.24~2.4m/min | 9.74kw | |

5000mm | 中 控 | 200~1800mm | 200-800mm | 4000~15000mm | 0.24~24m/min | 10.44kw | |

5000mm | 侧控 | 200~2200mm | 200-800mm | 4000~15000mm | 0.24~24m/min | 10.44kw | |

| 5500mm | 中控 | 200~2200mm | 200-800mm | 4000~15000mm | 0.24~24m/min | 10.44kw |

5500mm | 侧控 | 200~2500mm | 200-800mm | 4000~15000mm | 0.24~24m/min | 10.44kw | |

LHT | 1600mm | 中控 | 200~2500mm | 200-800mm | 4000~15000mm | 0.24~24m/min | 9.74kw |

CBH | 1500mm |

| 200~1200mm | 160-600mm | 4000~15000mm | 0.24~2.4m/min | 7.2kw |

MB15 | 3000mm |

| 200~1500mm | 160~600mm | 4000~15000mm | 0.24~24m/min | 9.74kw |

H-beam flange straightening machine: This machine is specially used for the H-beam flange distortion straightening, which includes hydraulic and mechanical straightening types. The structure of the mechanical flange straightening machine is simple, with convenient and reliable operation. The hydraulic type straightening has a strong straightening force and high automation, which was developed first by us. The straightening roller and powered roller are made of good alloy steel, which is made after heat-treating for long life.

类型Type | 机械矫正机 | 液压矫正机 | ||

HTJ-600 HTJ-800 | YTJ-60 YTJ-80 | |||

翼板厚度Flange thickness | ≤20mm | ≤40mm | ≤60mm | ≤80mm |

翼板抗拉强度Flange tension strength | ≤420MPa | ≤420MPa | ≤600MPa | ≤600MPa |

翼板宽度Flange width | 150~600mm | 200~800mm | 200-800mm | 200-1000mm |

腹板高度Web height | ≥160mm | ≥350mm | ≥350mm | ≥500mm |

矫正速度Straightening velocity | 5.7m/min | 17m/min | 6.4m/min | 6m/min |

装机功率Machine power | 9kw | 24.2kw | 37kw | 44kw |

设备重量Weight | 7T | 9T | 25T | 28T |