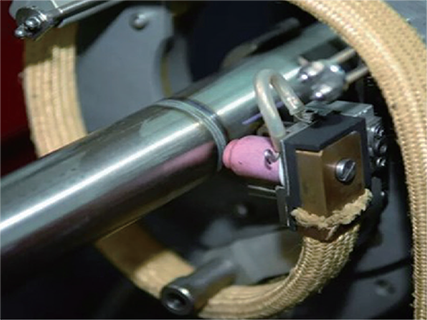

The equipment is specially designed for open-type & all-position TIG pipe-pipe welding. It adopts the wire-filling welding method, which is suitable for thickness 1.5-10mm pipe-pipe automatic welding. Applied for welding of carbon steel, stainless steel and other pipe-pipe joints. Optional for integrated wire feeder or external wire feeder with arc length swing function. It can be used with MK400 program-controlled welding power source to achieve all-position TIG pipe-pipe welding, with high repeatability of welding results and ideal welding effects. Mainly used in chemical, food, engineering installation, boiler, military and nuclear power and other industries.

Model | WP77 | WP130 | WP180 | WP230 | WP324 |

Weldable pipe diameter(mm) | Inner clampφ19.05~φ45 | Inner clampφ38.1~φ76 | nner clampφ50.8~Φ114.3 | Inner clampφ120~φ178 | nner clampφ150~φ230 |

Tungsten electrode diameter(mm) | φ2.4、φ3.2 | φ2.4、φ3.2 | φ2.4、φ3.2 | φ2.4、φ3.2 | φ2.4、φ3.2 |

Rotation speed(rpm) | 0.19~3.8 | 0.11-2.2 | 0.09~1.8 | 0.05~1.0 | 0.026~0.52 |

Protective gas | Argon | Argon | Argon | Argon | Argon |

Cooling method | Water cooling | Water cooling | Water cooling | Water cooling | Water cooling |

Cooling flow | ≥600 | ≥600 | ≥600 | ≥600 | ≥600 |

Yack width (mm) | 20 | 40 | 40 | 40 | 40 |

Arc length height(mm) | 40 | 40 | 40 | 40 | 40 |

Wire diameter(mm) | φ1.0Standard | φ1.0Standard | φ1.0Standard | φ1.0Standard | φ1.0Standard |

Max wire feeding speed(mm/min) | 1800 | 1800 | 1800 | 1800 | 1800 |

Main dimensions(mm) |

|

|

|

| |

A | 220 | 300 | 375 | 425 | 550 |

B | 180 | 235 | 285 | 300 | 315 |

C | 112~132 | 132-172 | 184~224 | 195~235 | 230~270 |

D | 92 | 165 | 225 | 250 | 297 |

E | 82 | 132 | 182 | 232 | 328 |

F | 320 | 400 | 525 | 570 | 680 |

Dimensions(mm) | 370*220*320mm | 435*300*400mm | 445*375*525mm | 465*425*570mm | 430*610*680mm |

Weight (kg) | 5.5kg | 10.8kg | 19.5kg | 21.5kg | 36kg |