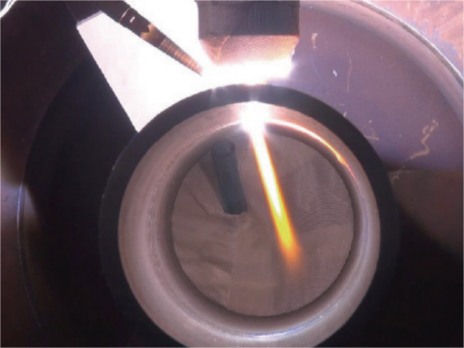

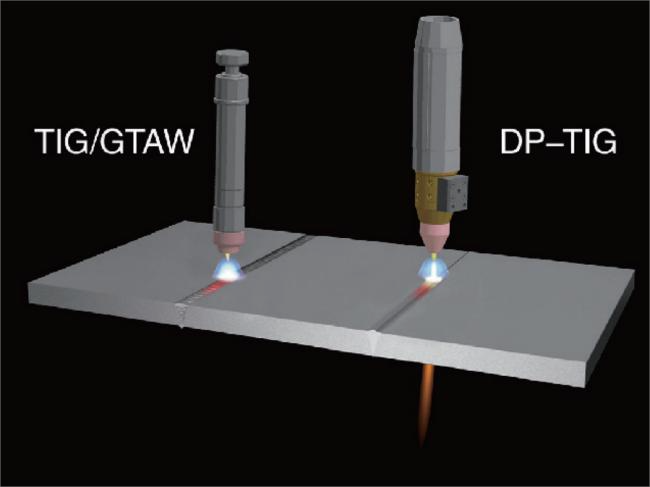

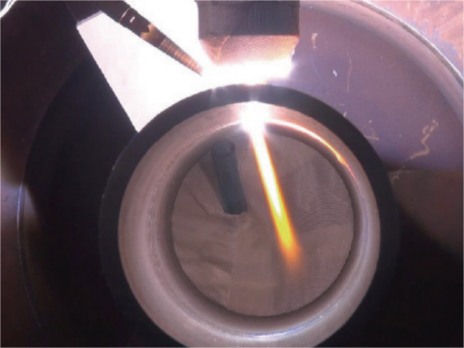

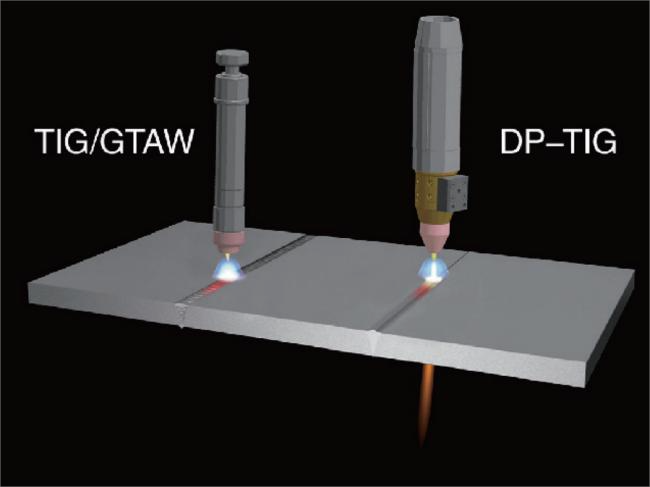

Deep penetration TIG welding (DP-TIG) process is a new efficient automatic welding process, using a new type of "Keyhole" (small hole) welding technology with special high-power welding torch to solve the problems of traditional TIG arc with low stiffness, shallow melting, low welding efficiency.

Overview: Deep penetration TIG welding (DP-TIG) process is a new efficient automatic welding process, using a new type of "Keyhole" (small hole) welding technology with special high-power welding torch to solve the problems of traditional TIG arc with low stiffness, shallow melting, low welding efficiency.

Welding technology parameters of austenitic stainless steel and its nickel-based alloys: | |||

Material thickness | Welding current (A) | Welding speed(mm/min) | Allowable welding gap(mm) |

3mm | 270 | 500 | 0.5 |

4mm | 325 | 350 | 0.5 |

6mm | 425 | 300 | 0.8 |

8mm | 480 | 280 | 1.0 |

10mm | 500 | 240 | 1.5 |

12mm | 520 | 220 | 1.5 |

Welding technology parameters of carbon steel and its alloy steel: | |||

Material thickness | Welding current (A) | Welding speed(mm/min) | Allowable welding gap(mm) |

3mm | 380 | 350 | 0.5 |

4mm | 400 | 300 | 0.5 |

6mm | 450 | 260 | 0.8 |

8mm | 500 | 325 | 1.0 |

10mm | 560 | 220 | 1.5 |

Welding technology parameters of titanium alloy: | |||

Material thickness | Welding current (A) | Welding speed(mm/min) | Allowable welding gap(mm) |

3mm | 280 | 500 | 0.5 |

4mm | 320 | 500 | 0.5 |

6mm | 350 | 350 | 0.8 |

8mm | 430 | 300 | 1.0 |

10mm | 470 | 280 | 1.5 |

13mm | 520 | 240 | 1.8 |

15mm | 560 | 200 | 2.0 |

Note:The above welding parameters must be achieved under certain conditions: | |||

| 1.Tungsten electrode 6mm; |

| |

| 2.Shield gas is purified argon,flow rate 20 /min; | ||

| 3. The surface oxidation layer and oil pollution on the front and the back 4. The product gap is less than the allowable gap list in the table

| ||