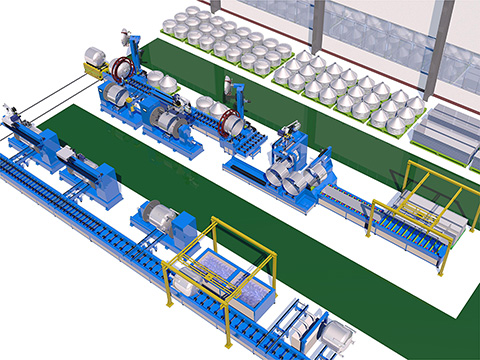

The tank manufacturing automation production line developed by our company integrates automated manufacturing equipment for multiple processing procedures, including steel plate entering & conveying, steel plate rolled into round, butt longitudinal seam welding, cylinder rounding, cylinder splicing girth seam welding, head joint girth welding and flaw detection. Through the supporting self-developed remote centralized control system and high-efficiency automated welding machine, the automated processing and production of the tank body are realized, the manufacturing hours are reduced, and the welding quality and production efficiency are effectively improved.