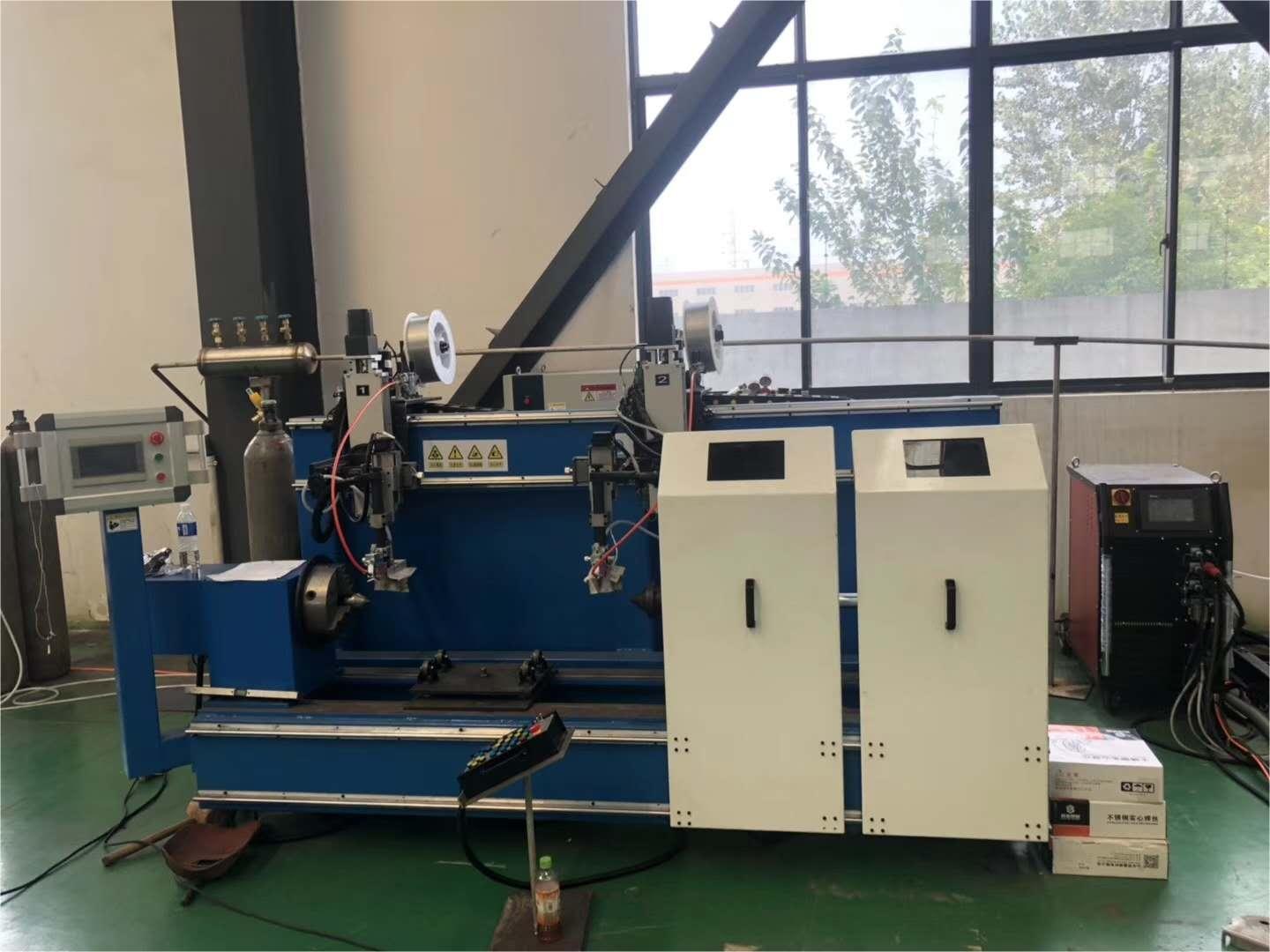

The circular seam auto welding tools are sorted as the horizontal and the vertical models, its driving mode has chuck type and friction type. The applied industries involve containers, food machinery, oil cylinders, pipe flanges, storage tanks, water heating pipelines, oil pipelines, nuclear storage tanks, construction machinery, central air condition, heat exchangers, tube-plate welding and so on. Suitable for welding of carbon steel, stainless steel, aluminum alloy, titanium alloy, copper and so on, and can be equipped with single welding torch or double welding torches according to customer’s

requirements. Equipment structure is reasonable and easy to operate, using touch screen and PLC programmed control, coupled with intelligent detection system, can do all-positions circular seam welding.

Model | Small vessels | hydro-cylinder |

Max welding diameter(mm) | φ1200mm | φ300mm |

Min welding diameter(mm) | φ300mm | φ50mm |

Max welding length(mm) | 3000mm | 3000mm |

Rotational speed(rpm) | 0.05~1.0rpm | 0.1~2.0rpm |

Speed control mode | Stepless speed regulation | Stepless speed regulation |

Welding torch adjust angle() | ±45° | ±45° |

Spindle motor | Variable frequency/servo motor | Variable frequency/servo motor |

Pneumatic travel | 500mm | 250mm |

Welding torch function | Tracking+Swing(optional) | Tracking+Swing(optional) |

Bracket method | Pneumatic | Pneumatic |

Vertical stroke of carriage(mm) | 450mm(electric) | 300mm(electric) |

Arc lateral swing carriage stroke | 60mm | 60mm |