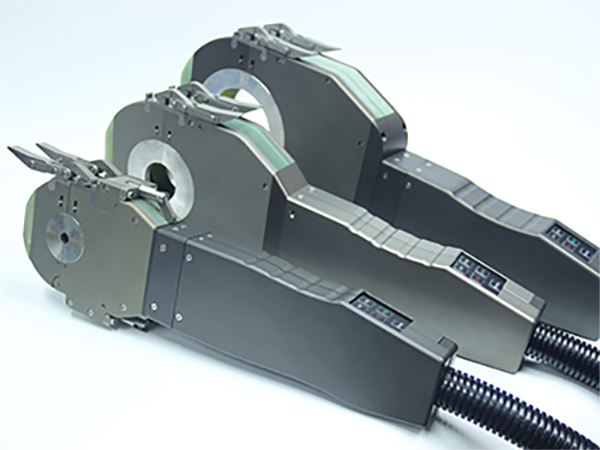

The equipment is specially designed for sealed type & all-position TIG pipe-pipe welding. It adopts the self-melting welding method, which is suitable for thickness 1.5-3mm pipe-pipe automatic welding. Applied for welding of carbon steel, stainless steel and other pipe-pipe joints. Optional for integrated wire feeder or external wire feeder with arc length swing function. It can be used with MK200 program-controlled welding power source to achieve all-position TIG pipe-pipe welding, with high repeatability of welding results and ideal welding effects. Mainly used in chemical, food, engineering installation, boiler, military and nuclear power and other industries.

Model | TC38 |

| Torch rotation speed | 0.2657~5.3145rpm |

Weldable pipe diameter(mm) | 6~38.1mm |

| Protective gas | Argon |

Maxwall thickness of weldable | 3mm |

| Cooling method | Water cooling |

Main welding material | Carbon steel, stainless steel, Tialloy |

| Cooling flow | ≥450m/min |

Main power supply | MK200 |

| External dimensions | 355*115*37.8mm |

Maxwelding current(A) | 85A 40%/65A 60%/45A 100% |

| Weight (kg) | 3.5kg |

|

|

|

|

|

Model | TC78 |

| Torch rotation speed | 0.194~3.877rpm |

Weldable pipe diameter (mm) | 19.05~76.2mm |

| Protective gas | Argon |

Max wall thickness of weldable | 3mm |

| Cooling method | Water cooling |

Main welding material | Carbon steel, stainless steel, Tialloy |

| Cooling flow | ≥450mVmin |

Main power supply | MK200 |

| External dimensions | 425*170*38mm |

Max welding current (A) | 100A 40%/75A 60%/55A 100% |

| Weight (kg) | 5kg |

|

|

|

|

|

Model | TC118 |

| Torch rotation speed | 0.092-1.924rpm |

Weldable pipe diameter(mm) | 38.1~114.3mm |

| Protective gas | Argon |

Max wall thickness of weldable | 3mm |

| Cooling method | Water cooling |

Main welding material | Carbon steel, stainless steel, Tialloy |

| Cooling flow | ≥450mVmin |

Main power supply | MK200 |

| External dimensions | 482*210*50mm |

Max welding current(A) | 120A 40%/100A 60%/80A 100% |

| Weight (kg) | 6.5kg |